Hardcarb® re-furbishment services

for reclamation of critical high-value spare parts

In various mineral-processing industries, wear-related maintenance is associated with production losses during stoppage and restart of the production. To reduce the dramatic effects of downtime, Hardcarb provides refurbishment services to rebuild the critical parts back to as-new condition. Apart from this, expensive worn-out components can be brought back to better-than-original conditions for further reuse at a fraction of the cost. Some examples:

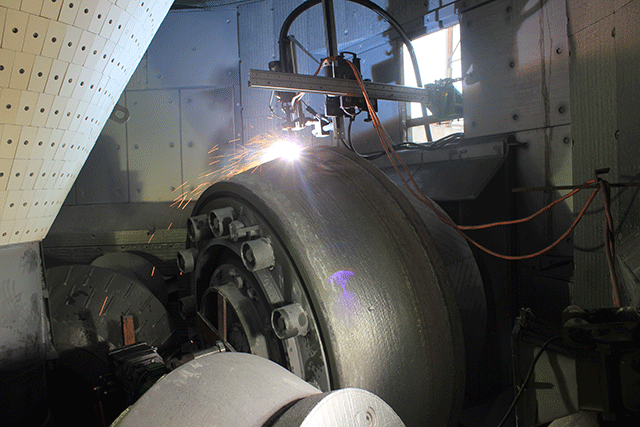

With close to 20 years of experience in this field, Hardcarb has all the necessary know-how, equipment, experience and expertise to carry out such critical jobs successfully at our workshops or in-situ at client sites using our powerful automated equipment.

Hardcarb also supports customers in reverse engineering and developing high value spares such that their lifetimes can be increased without any loss of reliability. Advanced computer analyses are employed in many cases for checking mechanical reliability.