Hardcarb® deposition welding materials

for fast and efficient solutions to onsite wear problems

Many different wear problems can be solved efficiently and quickly onsite with Hardcarb® deposition welding materials. Our trained technicians are also available for customers to carry out such welding jobs at site. Each Hardcarb® alloy is engineered with over 25 years of hardsurfacing experience by a team of highly qualified metallurgists. All know-how pertaining to different base material welding procedures are well documented and available for customers. Our alloys are available in many different material specifications:

Hardcarb hardfacing welding consumables are used for all applications subject to abrasion, erosion, impact, temperature and corrosion. No matter what the application — whether it’s excavation, crushing, grinding, mixing, screening or conveying — you will always find the right solution for your specific requirements within our extensive alloy range.

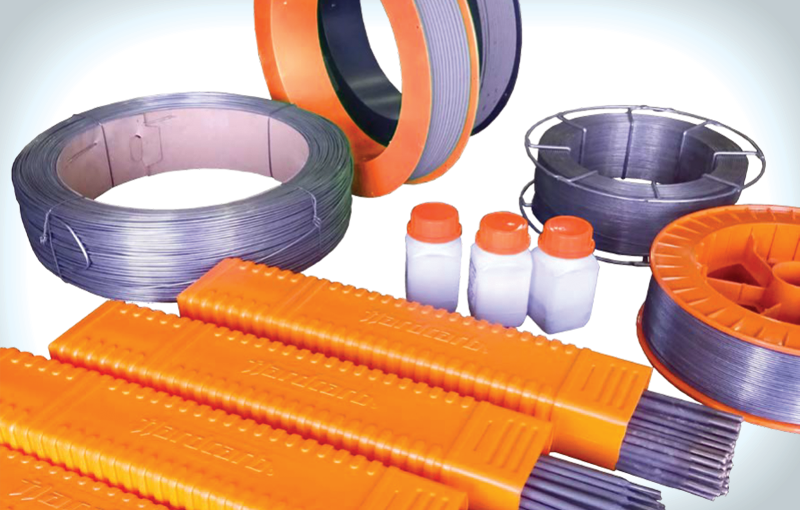

Available forms

Hardcarb® deposition welding materials are manufactured using proprietary formulations and are available in various forms to suit the application requirement.