Hardcarb® hardfacing services

in our workshops or “in-situ” at client sites

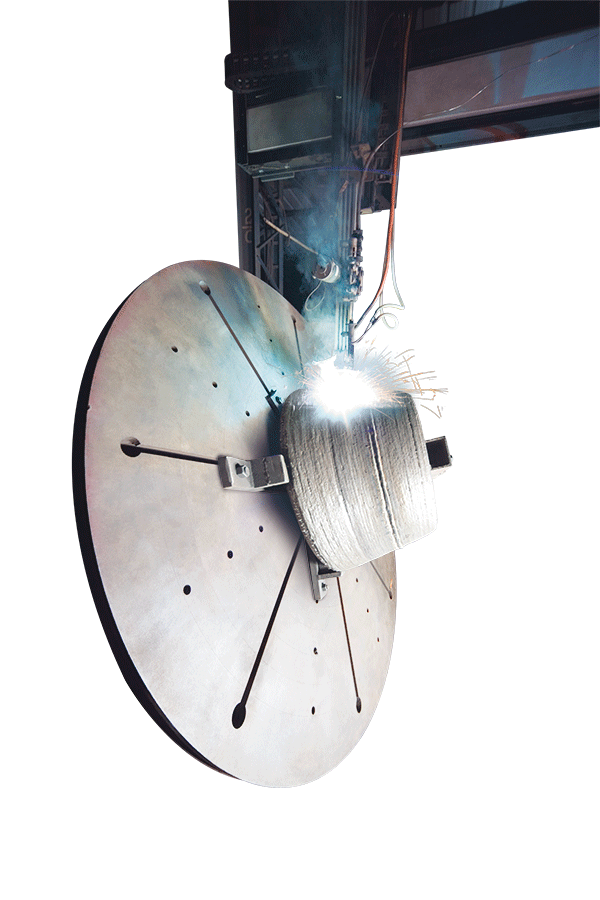

One of the major activities at Hardcarb is providing specialized hardfacing services in-house or in-situ at client site using our own advanced welding consumables and state-of-the-art machines. Our knowledge of service conditions of worn components enables us to recommend the appropriate welding method and welding consumables to provide exceptional component service life, always exceeding the original performance.

In partnership with our customers and according to their specifications, Hardcarb offers a full range of services and solutions:

Since Hardcarb is a 360 degree solution provider with a comprehensive portfolio of wear protection products, we are not limited to just one solution. This enables us to carry out an unbiased examination, and to propose designs for your plant components and assemblies which offer the ideal techno-economically optimized solution.