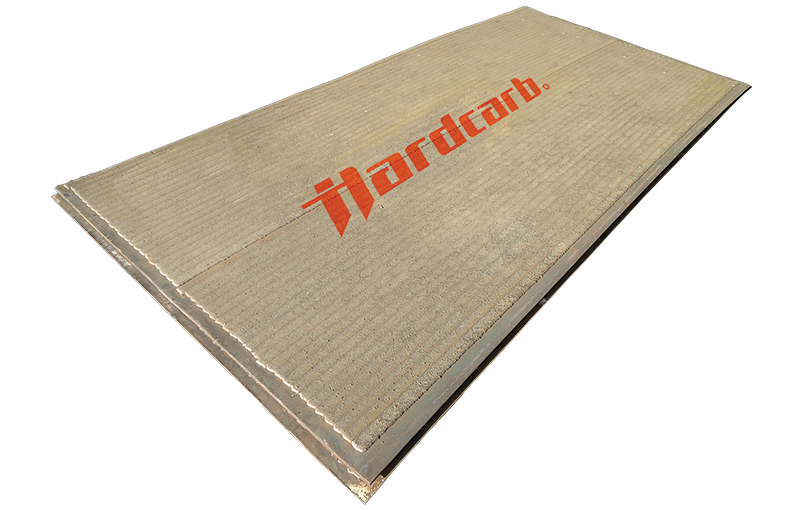

Hardcarb® composite wear plates

for reliable, all-purpose wear protection

Other generic names:

/High Chromium Carbide Overlay composite wear plate, CCO overlay plate

/Hardfaced plates, high carbide wear resistant steel

/bimetal wear resistant chromium carbide wear plate

/abrasion resistant wear plate, abrasion resistant steel

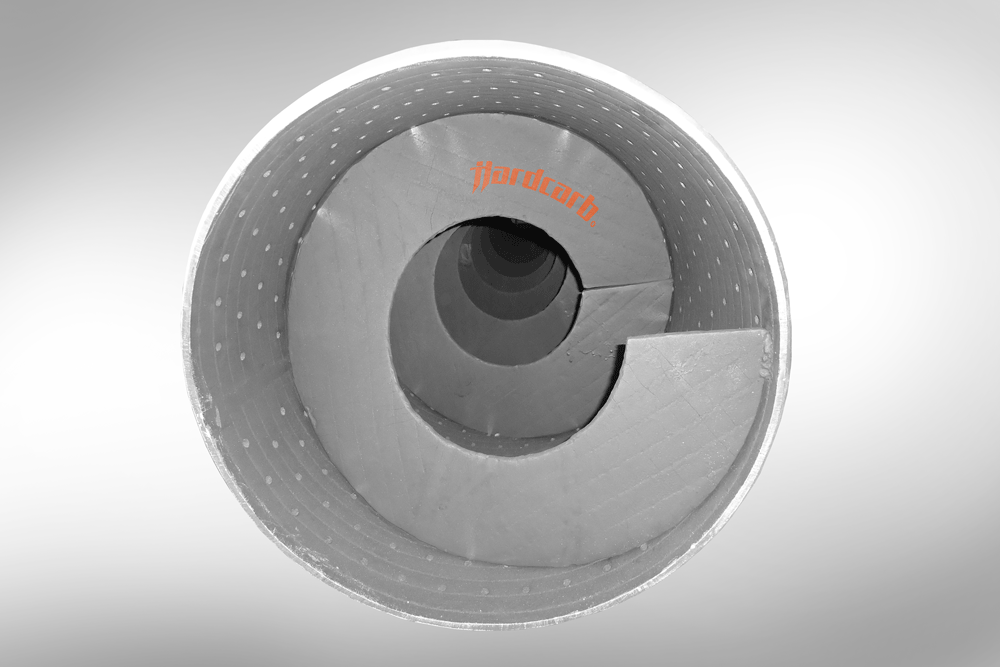

Hardcarb composite wear plates consist of a steel backing plate on which a very hard wear-resistant alloy is deposited using a proprietary Carb-o-inject welding process. This alloy may contain hardphases of extreme hardnesses depending on the application conditions and expected service life (hardlayer contains stress-relieving hairline cracks). Common hardphases include:

Hard coatings from 1.0 mm upto 15.0 mm are easily achievable, though most common are the 3mm to 8 mm thickness range. Backing plate can be any weldable steel suited for the application.

Why Hardcarb® ?

Hardcarb composite wear plates should not be compared with sheets coated using conventional hardfacing techniques such as flux-cored wire welding, submerged arc welding etc. Our wear plates are manufactured using proprietary carb-o-inject process which is still today, one of the only rare techniques of obtaining very hard, dense, closely packed primary carbides from top to bottom of the hardfacing deposit. It is this unique property that ensures the superior performance of Hardcarb wear plates as compared to all competitors worldwide. Supply alternatives include:

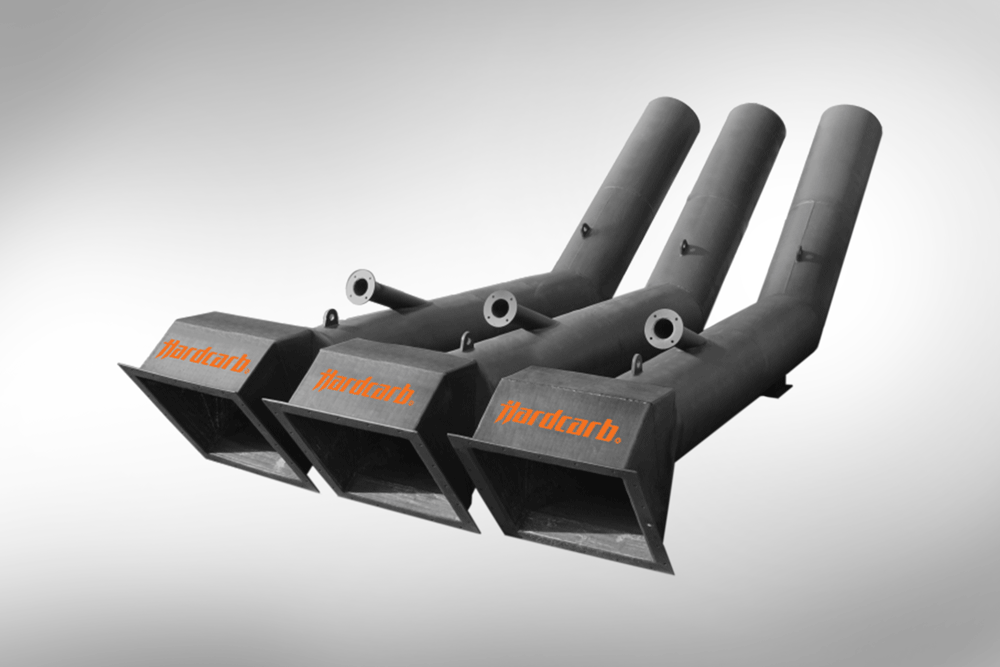

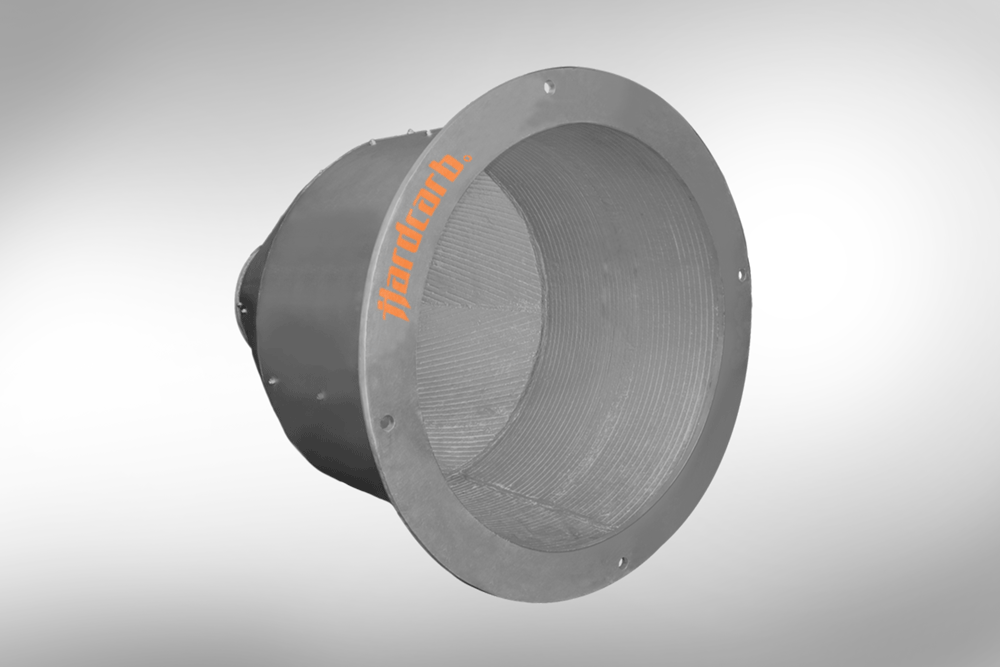

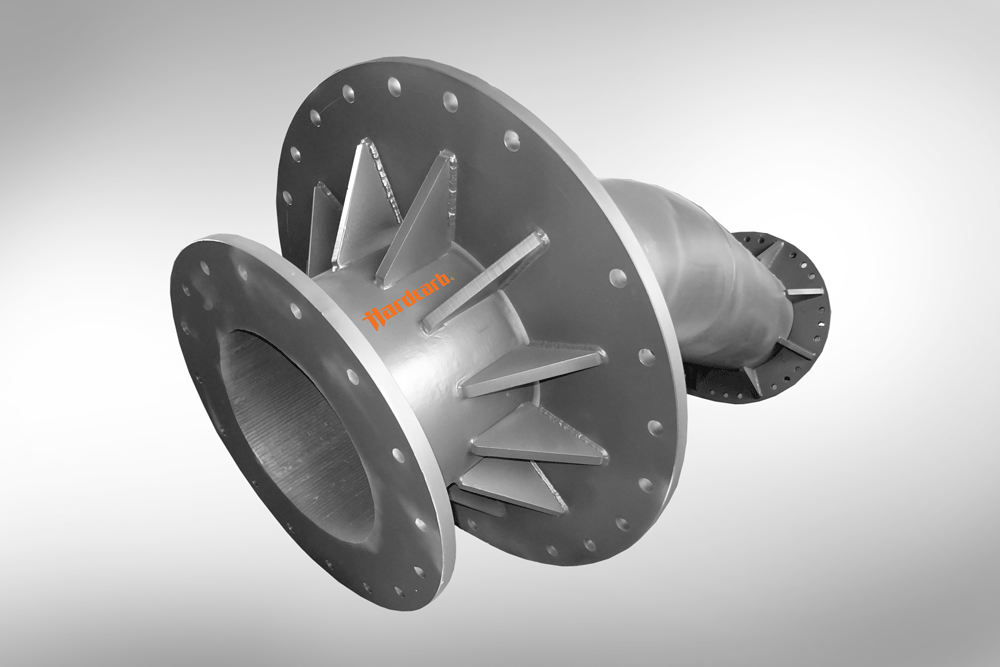

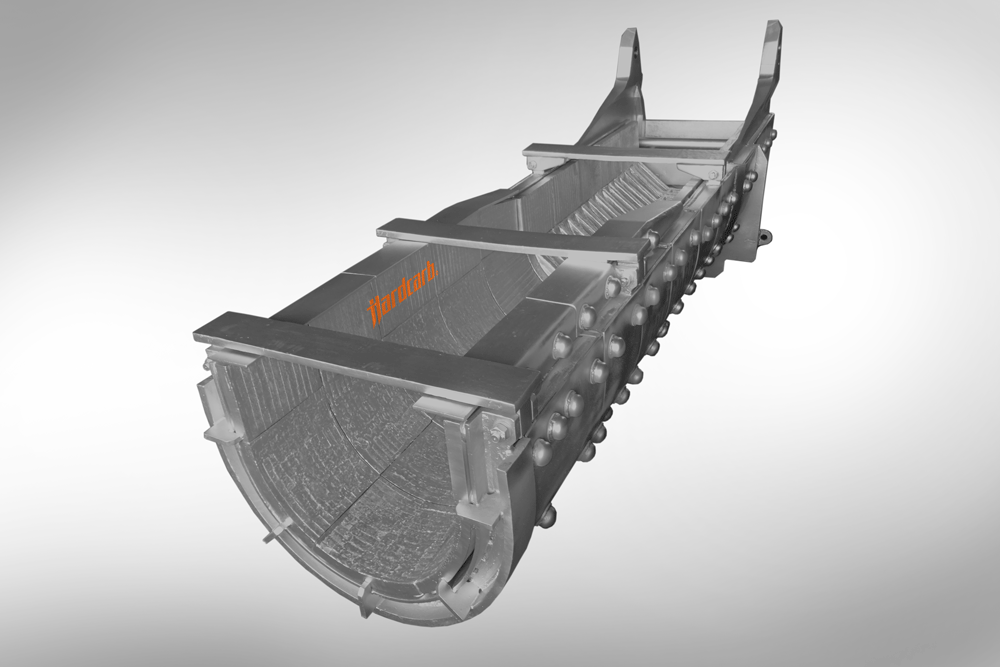

Typical applications

Typical applications include protection of large surface areas which are under high mechanical load and require great operational reliability. Examples include: