Key Portfolio

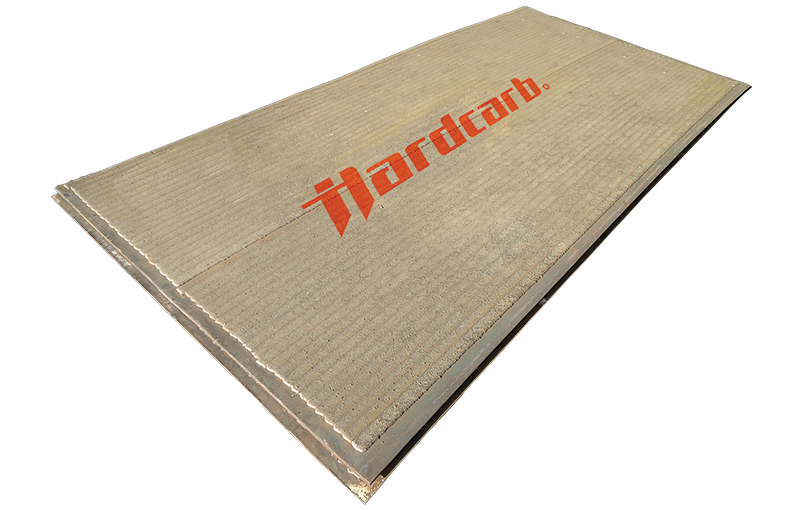

composite wearplates

Hardcarb composite wearplates consist of a steel backing plate on which a very hard wear-resistant alloy is deposited using a proprietary welding process. This alloy may contain hardphases of extreme hardnesses depending on the application conditions and expected service life.Common hardphases include

+ chromium carbides

+ complex carbides

+ tungsten carbides

+ metallic borides or borocarbides

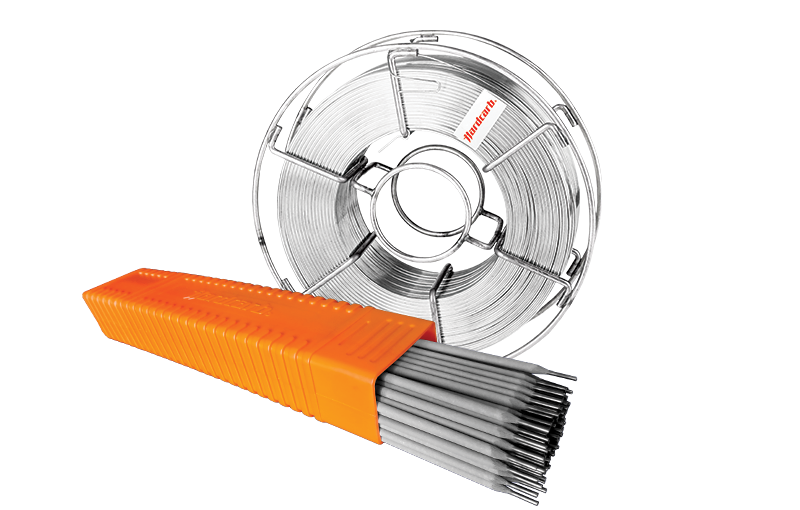

welding consumables

Hardcarb deposition welding materials are available in many different material specifications – Hardfacing, repair and buffering, stainless steels, dissimilar steel joining etc. Available as:

+ Slag-free covered and tubular stick electrodes

+ Flux-cored tubular wires

+ Atomized powders

hybrid castings

Hardcarb hybrid castings are a new generation of pre-hardfaced cast parts. High thickness hardfacing is applied using special procedures on relatively inexpensive base castings to achieve multi-fold increase in service life.

Typical applications include:

+ vertical mill grinding elements

+ sinter crushers

+ crusher hammers

sintered hard materials

Hardcarb sintered materials provide unparalleled increase in service life of severe wearing components. The hardmetals are applied by a special brazing process and are custom-designed for abrasion, impact, temperature, erosion and/or corrosion resistance.

High alumina ceramics also form part of this portfolio. These can be bolted, glued, welded using inserts, embedded in rubberized base etc.

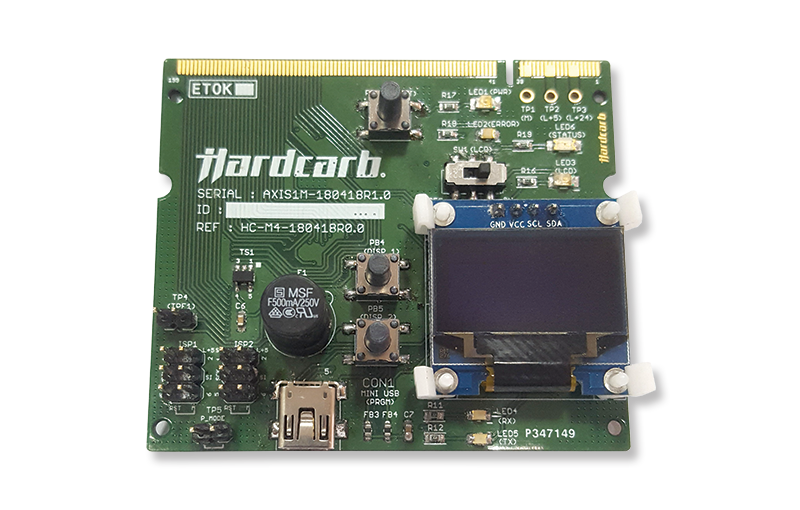

automation

Hardcarb automation is in a position to work closely with all customers for developing specialized hardfacing solutions. One of the highlights is the ultra portable “in-situ” hardfacing machine which can be used to carry out complicated hardfacing operations with remarkable ease and accuracy.