- Home

- Main Catalog

- Buffer layers - Build up - Cladding - Joining

- Dissimilar & stainless steels

- Nicrolloy 25.20

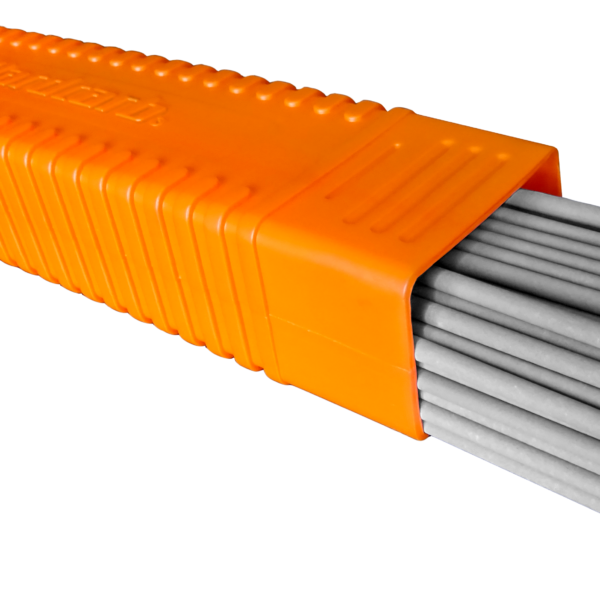

Nicrolloy 25.20

A versatile electrode suitable for joining corrosion-proof, highly heat-proof and non-scaling CrNi steels which are subject to service temperatures up to 1200° C. The electrode can also be used to join difficult-to-weld steels such as armour plate and ferritic stainless steels, as well as dissimilar steels. The weld metal alloy is highly hot-crack-proof and is optimally designed for welding wrought or cast 25%Cr-20%Ni (310 type) parent alloys with up to 0.25% carbon. These consumables can also be used for mixed welding and dissimilar joints including those where PWHT is applied.

Weld deposit characteristics:

The weld metal is fully austenitic with a ferrite number of 0 and possesses high strength, high ductility, good toughness and creep strength. The composition has been carefully balanced to give good resistance to hot cracking. The fully austenitic weld metal can be useful for specialised applications requiring low magnetic permeability (typically <1.01).

The electrode is characterized by a stable arc, which is easy to strike and re-strike. It produces smooth finely rippled welds of radiographic quality along with easily removable slag.

Recommended uses and applications

» welding of 310 type austenitic stainless steels, straight chromium stainless steels, difficult-to-weld steels, steels of relatively high harden ability, clad steels etc. e.g. heat shields, furnace parts and high temperature piping, ducting.

» for buffer layers and surfacing.

» joining of clad steels and dissimilar joints between stainless and mild or low alloy steels.

» for cryogenic installations involving any of the standard 300 series austenitic stainless steels.

Additional info

Anti-wear suitability

| Metal-to-Metal friction Metal surfaces in relative motion forced into contact with or without lubricant. Degradation by the formation of micro-welds between the contacting surfaces. | - |

| High pressure abrasion Wear by relative movement under pressure of mineral particles of suitable hardness, shape and texture to remove material from the metal surface, leaving superficial deformation. | - |

| Cavitation Tearing out of grains from the metal surface by the formation and implosion of bubbles in a liquid in rapid motion. | - |

| Mechanical fatigue Fatigue and formation of cracks in surface regions due to tribological stress cycles that result in the separation of material. | - |

| Thermal fatigue Cyclic exposure to high temperatures leading to permanent deformation by alternate expansion and contraction. Alteration of the structure and properties of the material. | - |

| Hot oxidation Creation of a poorly adhering oxide layer that reforms constantly. Degradation by loss of material thickness. | - |

Workability

| Work hardening Work hardening is the process of making a metal harder and stronger through plastic deformation. When a metal is plastically deformed, dislocations move and additional dislocations are generated. | |

| Edge retention Suitability for creating sharp edges and retaining them during operation. | |

| Machining Machinability is the ease with which a metal can be cut (machined) permitting the removal of the material with a satisfactory finish at low cost. | Highly suitable. |

Mechanical properties

| Yield strength | > 400 MPa |

| Tensile strength | 560 - 620 MPa |

| Elongation A5 | > 32% |

| Impact strength | > 80 J (+20°C) |