- Home

- Main Catalog

- Buffer layers - Build up - Cladding - Joining

- Dissimilar & stainless steels

- Nicrolloy 25.12

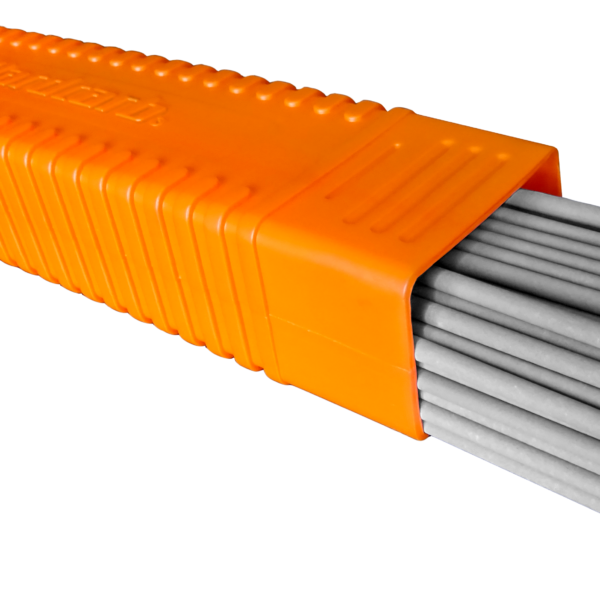

Nicrolloy 25.12

Overalloyed low carbon electrode designed for dissimilar welding between non-molybdenum-alloyed stainless steel and mild or low alloy steels. Its tolerance to dilution is exploited in joining stainless types 410, 304L, 321 and 316L to mild and low alloy steels such as stiffeners, brackets and other attachments. It is also well suited for joining difficult-to-weld steels, for corrosion-proof plating and as a buffer layer when performing overlay welding on mild steels, providing an 18Cr 8Ni deposit from the very first layer. Wrought and cast steels of 23Cr-12Ni type (eg. ASTM 309) can be welded if the service requirement is corrosion resistance below 300°C. The weld metal ensures crack-proof deposits and is scale-resistant up to 1000°C in air.

Weld deposit characteristics:

The microstructure is austenite with ferrite in the range 10-20FN. The high alloy content and ferrite level enable the weld metal to tolerate dilution from mild and low alloy steels without hot cracking or brittle structures. Useful for resistance to corrosion and to high temperature scaling up to about 1000°C, but not recommended for structural applications above 300°C or for welds to be post-weld heat treated, owing to embrittlement. The stick electrode is weldable in all positions except vertical-down. It is distinguished by a stable arc, minimal spatter, and very good slag removal.

Recommended uses and applications

» dissimilar joints between stainless and mild or low alloy steels.

» buffer layers on mild and low alloy steels prior to overlays with 308L or 347 type stainless steels.

» interface runs in clad steel joints.

» joining of clad steels and dissimilar joints between stainless and mild or low alloy steels.

» welding of 309 type austenitic stainless steels.

» joining ferritic-martensitic 410 and 430 type stainless steels.

Additional info

Anti-wear suitability

| Metal-to-Metal friction Metal surfaces in relative motion forced into contact with or without lubricant. Degradation by the formation of micro-welds between the contacting surfaces. | - |

| High pressure abrasion Wear by relative movement under pressure of mineral particles of suitable hardness, shape and texture to remove material from the metal surface, leaving superficial deformation. | - |

| Cavitation Tearing out of grains from the metal surface by the formation and implosion of bubbles in a liquid in rapid motion. | - |

| Mechanical fatigue Fatigue and formation of cracks in surface regions due to tribological stress cycles that result in the separation of material. | - |

| Thermal fatigue Cyclic exposure to high temperatures leading to permanent deformation by alternate expansion and contraction. Alteration of the structure and properties of the material. | - |

| Hot oxidation Creation of a poorly adhering oxide layer that reforms constantly. Degradation by loss of material thickness. | - |

Workability

| Work hardening Work hardening is the process of making a metal harder and stronger through plastic deformation. When a metal is plastically deformed, dislocations move and additional dislocations are generated. | |

| Edge retention Suitability for creating sharp edges and retaining them during operation. | |

| Machining Machinability is the ease with which a metal can be cut (machined) permitting the removal of the material with a satisfactory finish at low cost. | Highly suitable. |

Mechanical properties

| Yield strength | > 400 MPa |

| Tensile strength | 560 - 620 MPa |

| Elongation A5 | > 32% |

| Impact strength | > 50 J (+20°C) |