- Home

- Main Catalog

- Buffer layers - Build up - Cladding - Joining

- Dissimilar & stainless steels

- Nicrolloy 18.8.6

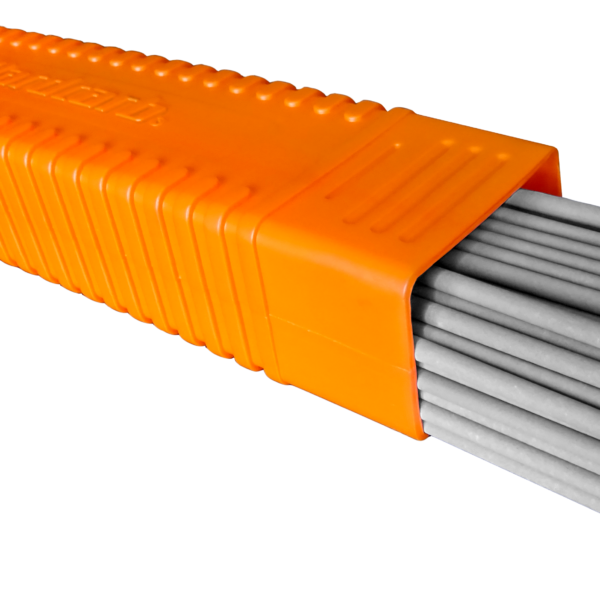

Nicrolloy 18.8.6

A fully austenitic stainless steel deposit with high Mn content. Suitable for welding and cladding on crack-sensitive, difficult-to-weld steels (> 0.7 % C) and for tough joints and claddings on heat resistant stainless steels and cast steels. Perfectly suited for joining austenitic to ferritic base materials at service temperatures up to 300° C. It can also be used for buffer layers prior to hardfacing and for repairing manganese steel.

Weld deposit characteristics:

Fully austenitic stainless steel deposit with high Mn-content. The weld deposit is stainless, heat resistant and non-scaling up to 850° C, resistant to sulphurous furnace gases at max. 500° C. The strain-hardenable, non-magnetic deposit work-hardens to about 340 HB. The special alloying increases the resistance against cracking, corrosion, oxidation, abrasion and cavitation.

The deposit is excellent for unlimited build-up layers on “Hadfield” manganese steel and also on carbon steel prior to chromium carbide hardfacing deposit.

Recommended uses and applications

Surfacing and building up manganese steel components used in:

» railway applications (rails, switches, crossings, tongues)

» quarries and mines (crusher jaws, excavator and grab teeth, mill hammers, blowbars, gyratory crusher, dredge cutters)

Other common uses:

» for dissimilar joints between Mn and construction steels

» as buffer layers prior to hardfacing

Additional info

Anti-wear suitability

| Metal-to-Metal friction Metal surfaces in relative motion forced into contact with or without lubricant. Degradation by the formation of micro-welds between the contacting surfaces. | Highly suitable |

| High pressure abrasion Wear by relative movement under pressure of mineral particles of suitable hardness, shape and texture to remove material from the metal surface, leaving superficial deformation. | - |

| Cavitation Tearing out of grains from the metal surface by the formation and implosion of bubbles in a liquid in rapid motion. | Suitable |

| Mechanical fatigue Fatigue and formation of cracks in surface regions due to tribological stress cycles that result in the separation of material. | - |

| Thermal fatigue Cyclic exposure to high temperatures leading to permanent deformation by alternate expansion and contraction. Alteration of the structure and properties of the material. | - |

| Hot oxidation Creation of a poorly adhering oxide layer that reforms constantly. Degradation by loss of material thickness. | Suitable |

Workability

| Work hardening Work hardening is the process of making a metal harder and stronger through plastic deformation. When a metal is plastically deformed, dislocations move and additional dislocations are generated. | |

| Edge retention Suitability for creating sharp edges and retaining them during operation. | |

| Machining Machinability is the ease with which a metal can be cut (machined) permitting the removal of the material with a satisfactory finish at low cost. | Suitable using carbide tools. |

Mechanical properties

| Yield strength | > 400 Mpa |

| Tensile strength | 600 Mpa |

| Elongation A5 | > 32% |

| Impact strength | > 32 J (-60°C) |