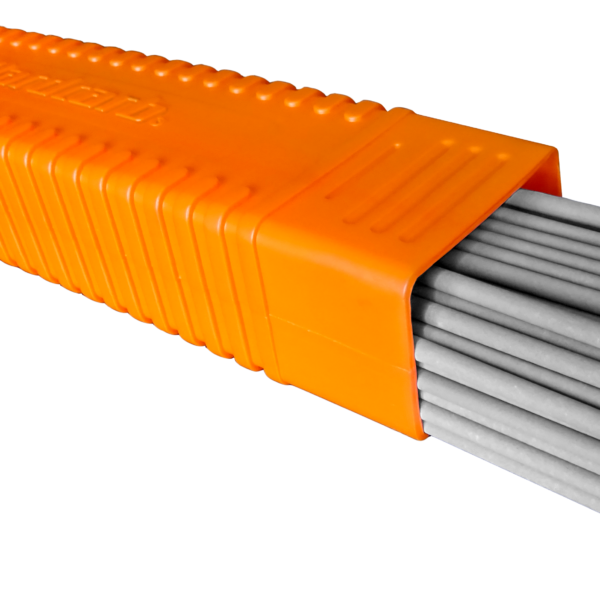

Hardcarb 5001

Cobalt base hardfacing alloy possessing excellent abrasion and corrosion resistance for applications such as pump sleeves, rotary seal rings, wear pads, expeller screws and bearing sleeves. It is the hardest of all the standard cobalt base alloys.

Weld deposit characteristics:

The deposit is a cobalt base alloy of austenitic-ledeburitic structure with embedded CrW carbides. It is the hardest of the standard Cobalt base alloys. The weld metal has exceptional resistance to metal-to-metal wear in corrosive media at high temperatures, where shocks are low to moderate. Excellent gliding characteristics, good to polish.

Only machinable with tungsten carbide tools or by grinding.

Recommended uses and applications

Typical applications:

» Cutting tools, shredding tools

» mixing and drilling tools

» hot working tools without thermal shock

» extrusion screws

» steam valves

» wire guides

» rubber and plastic mixers

Additional info

Anti-wear suitability

| Metal-to-Metal friction Metal surfaces in relative motion forced into contact with or without lubricant. Degradation by the formation of micro-welds between the contacting surfaces. | Suitable |

| High pressure abrasion Wear by relative movement under pressure of mineral particles of suitable hardness, shape and texture to remove material from the metal surface, leaving superficial deformation. | - |

| Cavitation Tearing out of grains from the metal surface by the formation and implosion of bubbles in a liquid in rapid motion. | - |

| Mechanical fatigue Fatigue and formation of cracks in surface regions due to tribological stress cycles that result in the separation of material. | - |

| Thermal fatigue Cyclic exposure to high temperatures leading to permanent deformation by alternate expansion and contraction. Alteration of the structure and properties of the material. | - |

| Hot oxidation Creation of a poorly adhering oxide layer that reforms constantly. Degradation by loss of material thickness. | Highly suitable |

Workability

| Work hardening Work hardening is the process of making a metal harder and stronger through plastic deformation. When a metal is plastically deformed, dislocations move and additional dislocations are generated. | |

| Edge retention Suitability for creating sharp edges and retaining them during operation. | |

| Machining Machinability is the ease with which a metal can be cut (machined) permitting the removal of the material with a satisfactory finish at low cost. | Not possible. Only grinding possible. |