WEAR PROTECTION

is in our DNA.

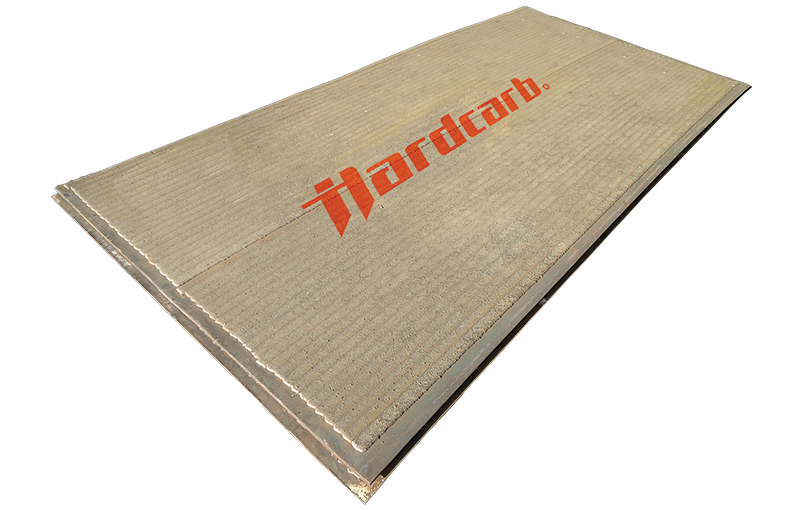

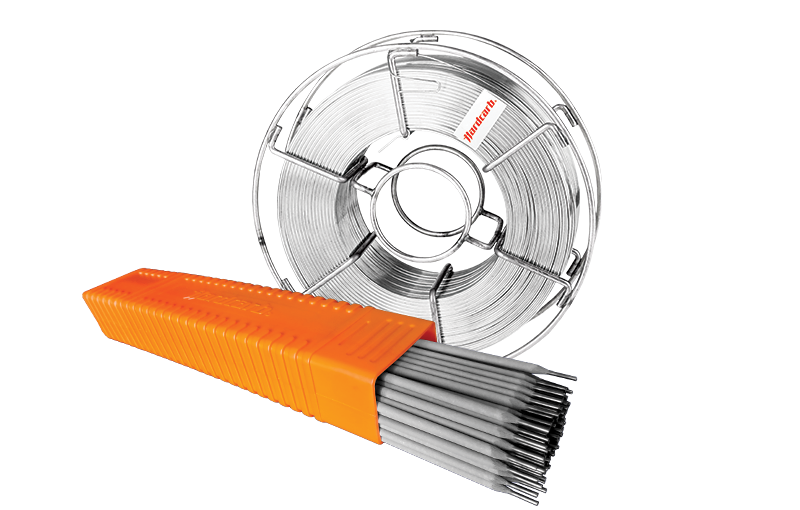

For more than two decades, Hardcarb® Technologies (Formerly known as Vautid-Shah Hardface Pvt. Ltd.) has been evolving and innovating fiercely to make its products obdurate and free from wear. Our continuous quest to fight wear is demonstrated from our 360o product spectrum designed to provide engineered hardfacing solutions. Our technology stack encompasses a wide array of advanced materials (Composite wear plates, slag-free hardfacing electrodes, cored tubular wires, pre-hardfaced castings, brazed hardmetals, atomized powders etc.), sophisticated processes, surfacing automation and intelligent engineering.

At Hardcarb, we understand the importance of operational reliability and power our products to be immune to wear. Our products fight abrasion, erosion, stress, impact and other wear-causing factors, which are often coupled with heat and corrosion. By focusing on wear problems in a wide spectrum of industries, Hardcarb has collected a vast amount of practical wear-related experience which is available to our clients in the form of reliable solutions.

Our technology stack

for engineered hardfacing solutions.

With a diversified range of high performance products, reliable services, automated equipment and engineered wear solutions; Hardcarb is your ideal partner for solving all wear problems. Our products ensure an increased industrial “uptime” and remain a tried and tested reference for protection under the harshest wear conditions.

sintered hard materials

Hardcarb sintered materials provide unparalleled increase in service life of severe wearing components. The hardmetals are applied by a special brazing process. High alumina ceramics also form part of this portfolio. These can be bolted, glued, welded using inserts, embedded in rubberized base etc.

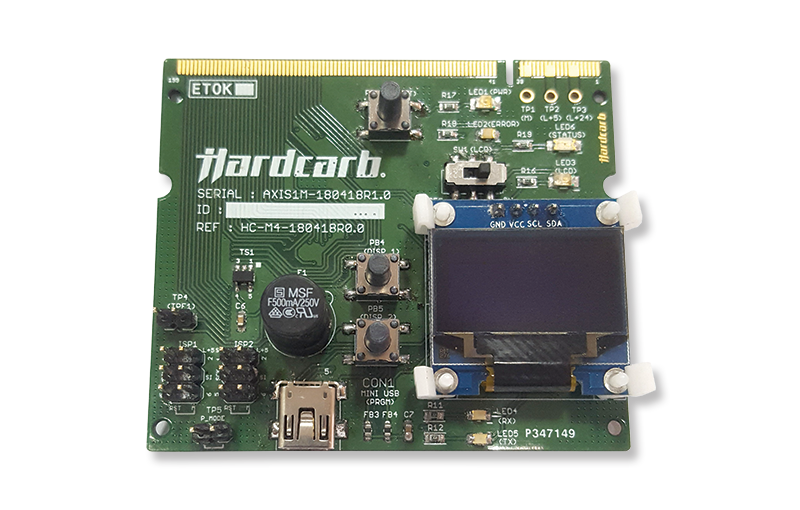

automation

Hardcarb automation is dedicated to developing high accuracy and highly reliable PLC/CNC/Robotic based hardfacing systems. The key to success is the integration of simple ideas with sophisticated yet maintenance-free components which are sourced from highly reputed manufacturers world-wide.

One of the highlights of Hardcarb automation is the ultra portable “in-situ” hardfacing machine which can be used to carry out complicated hardfacing operations with remarkable ease and accuracy. Minimal setup time, plug-and-play design and simple interface makes this a “must have” equipment in all bulk hardfacing shops.